CNC Laser

The Genesis

Back in 2012, my cousin and I delved into the world of 3D printing, exploring a hobbyist space that was still in its early stages. As I navigated through various CNC projects, little did I know that our journey was just beginning.

Fast forward to 2020, the tumultuous year of COVID-19. I found myself yearning for a new engineering challenge that could seamlessly blend my love for mechanical tinkering, software development, physical extremes, and creativity. However, there were constraints to consider – the entire project had to fit into my modest wooden shed while maintaining a reasonable level of safety.

Exploring Options

- CNC Plasma Cutter: Initially drawn to the CNC Plasma Cutter, my research unveiled potential challenges. The overhead of operating such a machine hinted at high maintenance costs due to significant wear and tear, compressed gases, and substantial stock expenses.

- CNC Router: The CNC Router emerged as another enticing option. However, my cousin had already embarked on constructing one, and we sought diversity in our projects.

- CNC Mill / Lathe: While CNC Mills and Lathes were considered, they fell short in terms of possibilities and creative outcomes. The high cost for stock and the limited yet powerful options left me unsatisfied.

- CNC Laser: Finally, the CNC Laser resonated with my passion. The prospect of working with a high-power laser beam to engrave and cut various materials without significant wear and tear captured my imagination. It seemed like the perfect fit for our ambitious yet confined venture.

Getting Started

I started out with a lot of respect for this project. I had no expectation that I could build this from scratch. It was clear to me that the best way to make progress is to start with a prototype which I know works, from which I can slowly go through a Ship of Theseus process and build a machine suitable for me.

The Ship of Theseus is a thought experiment about whether an object, after having had all of its original components replaced, remains the same object.

Just that my ship was supposed to receive a lot of upgrades on the way. :) So I set my sights on a cheap CNC Laser Cutter from China. I had no expectations, except that it works and comes in about the right case.

Eventually I found this device on eBay, which cost me around 1400€ including shipping. I placed the order and started waiting.

Safety

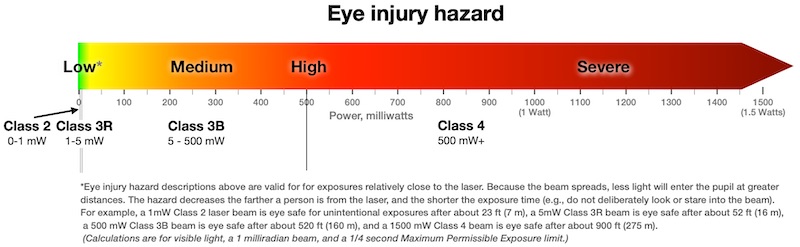

In the meantime I considered reading up on safety. It occured to me that I like seeing and operating a laser in Braille isn’t easy. Looking at the laser classification chart, I confirmed that there is no room for mistakes.

The interesting part is that the laser produces different kind of radiation depending on the situation. The most powerful one is the laserbeam itself which is characteristic “heat” radiation produced by CO2 Lasertubes. The less powerful but also dangerous one is radiation emitted by the laser hitting the material.

When the material is hit in an incredibly small point the laserbeam goes from an energy density of ~13,500 Watt / m² (150 W @ 6mm diameter beam) to 47,746,482 Watt / m² (150W @ 0.1mm beam). Anything that receives this much energy per square meter is going to immediately transition into a gas while glowing white hot. This can be extremely bright and damage the eye just like looking into the sun can.

WIP

Work in progress :)